WE MANAGE THE WHOLE PRODUCT CHAIN

We traslate the Idea of the designer into vision. Leather becomes a new surface, like white paper where something new could be created.

The leather is studied and researched in the best tanneries, where innovated products are made specifically for us.

Pattern is one of the most important process for making a sample. We work with Cad or on Dummy. We work closely to the customer to create the perfect fitting.

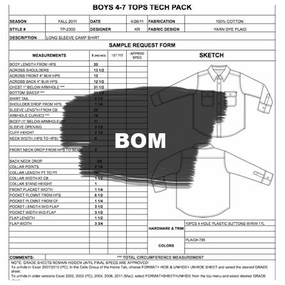

BOM helps to reduce the cost of production and to having the vision of all specific costs.

Cut is core of the process to make leather garments. Our cutter is used to works with all leather types; lamb skins, exotique skins, shearling and fur.

We use high quality sewing machine.We look for the innovation and new technologies in manufacturing to create something unique.

The perfect fit is our goal. We work with pattern maker and the tailor to realize perfect prototype.

After prototype, we do the sample. The first sample is done all partnering closely with the design office.

In addition to the development of high quality products, after the quality control, we delivery it in the hand of the customers.

Cassiopea S.r.l.

Zona Ind.le Terrafino

Via Volontari della Libertà, 47

Empoli, 50053, Firenze,Italia

CF / P.IVA 05626650484

Capitale Sociale €150.000,00

t. 0039 0571 584704

e. info@cassiopeasrl.it

© 2020 Cassiopea Srl - P.Iva 05626650484 - REA FI 561310 - Capitale Sociale € 150.000,00